WOOD MORPHOGENESIS

a brief research on material performance

The material research stems from the designers’ interest in the intrinsic hygroscopic properties of wood into creating an new aesthetics of intelligence informed by nature. During the process of swelling, pressure difference among cells results in energy storage within the micro structural system of wood fibres. By applying lamination constraints to the curved veneer before the rebound upon drying, energy can be stored. Through testing the process of lamination and deformation, specific system with highly variable geometry can be explored.

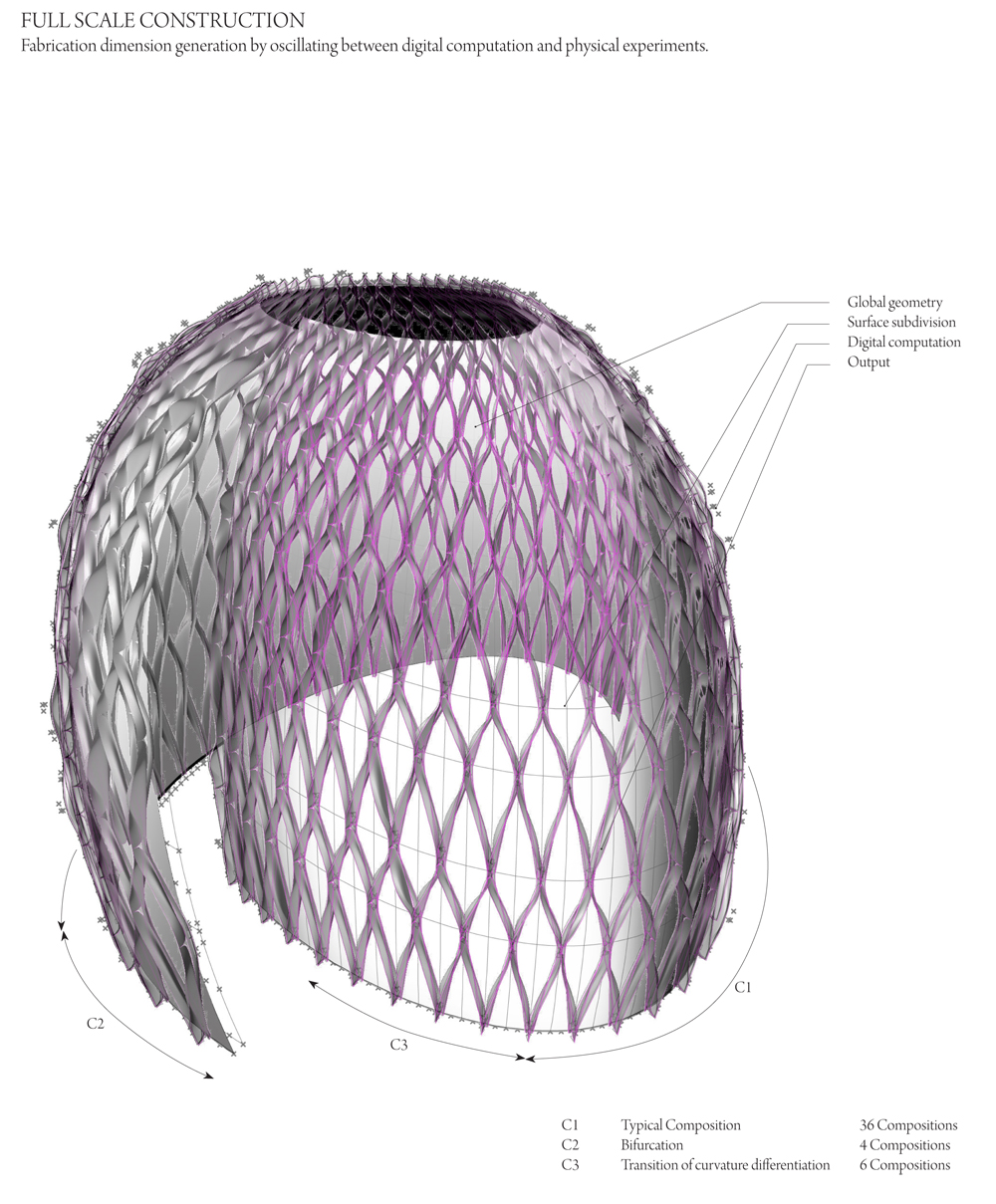

The computational tool predicted the approximate dimensions, global geometry and compositional curvature while physical tests are carried out to combine the material performance with computer-generated data for further evaluations…The relationship between the tools create unique interface for generation of the emergent typologies and global geometry of performance-oriented exploration as such.

The construction consisted of 46 groups of components while each of them consisted of 5 components: 36 identical groups of them are fabricated for the major structure, while 3 components in 6 groups of the total are fabricated differently for extreme curvature shift. Adding components and varying lamination position and area creates significant internal self-organization of the system and generate highly differentiated geometry.

Standardized and identical components are then performing with customized post-construction alterations without fabrication of unique components or pre-shaped elements. Standardization could actually achieve customization in the research without production large amount of waste.

Standardized and identical components are then performing with customized post-construction alterations without fabrication of unique components or pre-shaped elements. Standardization could actually achieve customization in the research without production large amount of waste.︎GO BACK